- #Mach3 cnc software stepper motor changing direction serial#

- #Mach3 cnc software stepper motor changing direction full#

- #Mach3 cnc software stepper motor changing direction Pc#

- #Mach3 cnc software stepper motor changing direction windows#

The only USB Breakout Board I am aware of intended solely to increase I/O capacity is one called ModIO that was developedĭesigns.

#Mach3 cnc software stepper motor changing direction windows#

It takes some very clever coding indeed for software like Mach3 to work on a parallel port, and each new release of Windows seems to make it a little harder.

#Mach3 cnc software stepper motor changing direction serial#

Unfortunately, while USB is the preferred replacement for the parallel port, and it has many advantages, it isn’t clear applications like CNC were considered for either the parallel or serial ports when they were first designed. The reason is that they are not high enough performance to maintain the exact timing relationships needed to produce a clean pulse train to control multiple servos or steppers. While there are boards that purport to simulate a parallel port with a USB connection, they don’t work for CNC applications. Second are boards used to increase the I/O capacity beyond what the parallel port provides.

#Mach3 cnc software stepper motor changing direction full#

First are full scale Motion Controllers, which we will cover in detail in a moment. USB breakout boards come in two varieties. I’ve done business with CNC4PC and Homann, and have actually used the CNC4PC board, and both companies were excellent to deal with. Suppliers of parallel breakout boards include: If you directly connect the parallel port without opto-isolation, you run the risk of destroying your computer’s expensive motherboard.

This feature isolates your PC’s motherboard from any bad connections, noise, or power surges that may occur in the rest of

Lastly, it is important to purchase a board that incorporates opto-isolation (you can look it up in the CNC Dictionary if you are curious).

Be sure to check with others to see if they have been successful with the particular combination you’d like to try. In addition, some card/PC combinations can be finicky when used with Mach 3. Obviously this won’t work with a laptop, because they have no PCI slots. It should be noted that you can add a second parallel port to most computers using a PCI card. For this reason, you either have a choice to “keep it simple”, or you will need to add one or more additional boards to get the job done. As you can imagine, these go quickly, especially if you are trying to connect an elaborate control panel to your machine. Boards typically support 11 or fewer outputs and only 5 inputs. Lastly, parallel ports have relatively few I/O channels. Laptops are a particular source of this kind of problem. Be sure to check whether the board you are looking at will be compatible with your PC. Some breakout boards work fine with this while others have problems. As a result, many later model PC’s use 3.3 volt signals instead of 5 volts.

#Mach3 cnc software stepper motor changing direction Pc#

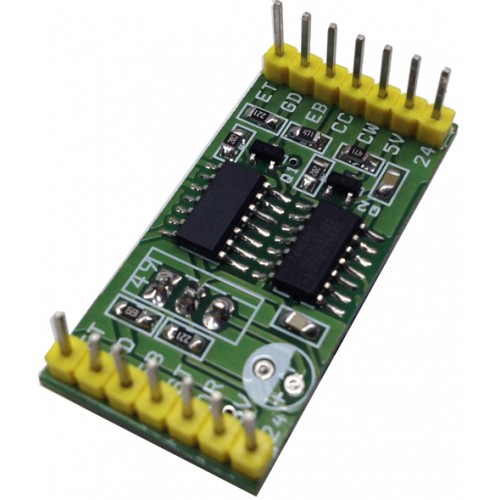

PC manufacturers are gradually phasing out parallel ports altogether in favor of USB, and in the meantime, they are sharply controlling the power consumption of these interfaces. The second limitation is that of compatibility. For better performance, use a Motion Controller (see below). For most low end applications, this is not a problem. You will be limited in how quickly you can send and receive the signals from the board, which may in turn limit the performance of your CNC. There are limitations on its performance, particularly when used with Windows software, such as with Mach 3. First, the parallel port itself is a bit of a throwback to the early days of the PC. They’re simple, and relatively inexpensive. These are the most commonly used type of breakout board. Parallel CNC Breakout Boards connect to your PC’s parallel port and convert those signals to screw terminals which you may then use in point-to-point wiring to connect up the rest of your system. Since the Motion Controller has no distractions (unlike a PC), and can focus totally on motion control, this enables much higher performance.ĬNC Breakout Boards… Parallel CNC Breakout Boards The role of a Motion Control is to relieve your PC control software from having to do all the work and move some of the most time critical parts of that work to a dedicated hardware device. In addition, many refer to USB Motion Controllers, such as the Smoothstepper, as “USB Breakout Boards”. Isolate the PC Motherboard from electrical problems that would otherwise fry the Motherboard. Translate the signals used to run a CNC machine to and from the signals a PC expects.Ģ. Simply put, the CNC Breakout Board has two functions:ġ. There are several different types of CNC Breakout Boards and related devices used to deliver this I/O (Input/Output) capability, including Parall el CNC Breakout Board s, USB Breakout Boards, keyboard emulators, and motion control boards. The CNC Breakout Board is used to interface between your PC and the various motor controls, relays, and other devices you want to control on a CNC machine. CNC Breakout Boards What Is a CNC Breakout Board?

0 kommentar(er)

0 kommentar(er)